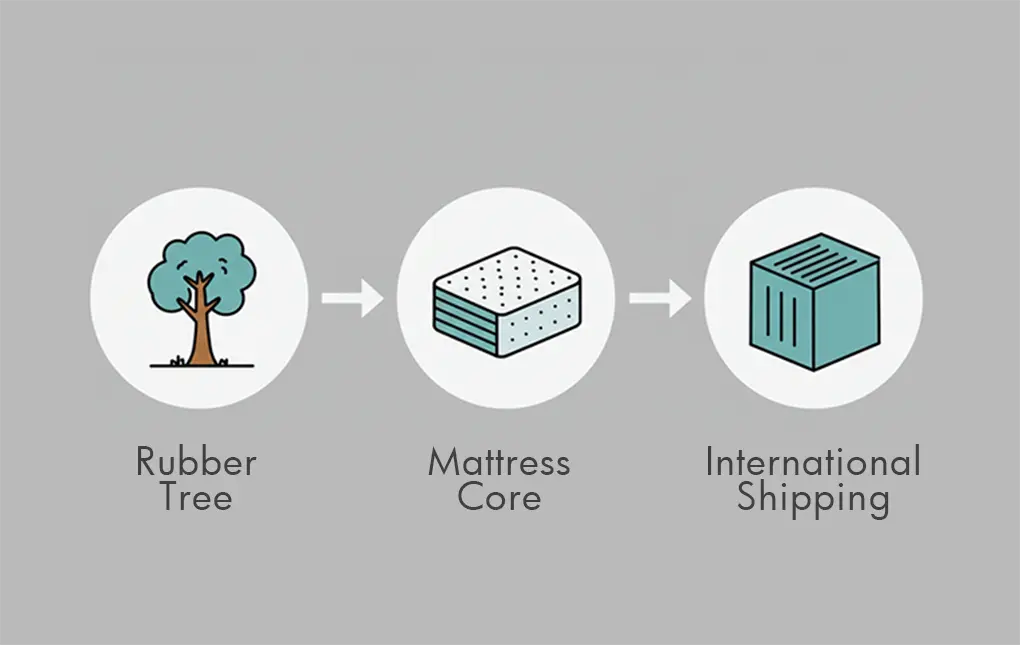

From Tree to Container: The Journey of a Malaysian Latex Mattress Core

As a buyer, understanding your supplier’s production process isn’t just a bonus it’s a necessity. At MAUS Industries, we believe in full transparency, which is why we’re giving you an inside look at how your latex mattress core is made from tapping the first drop of latex to loading it into a container bound for your factory.

1. Rubber Tapping: Where It All Begin![]() s

s

Malaysia is home to some of the world’s highest-grade rubber trees. Every core starts with latex milk tapped sustainably from Hevea brasiliensis trees. Our sourcing prioritizes:

- Environmentally responsible plantations

- Fair trade practices

- Clean tapping methods to prevent contamination

2. Filtration and Purification

Once harvested, the raw latex is transported to our certified production facility. Here, we filter out impurities and stabilize the liquid latex through:

- Controlled mixing

- De-ammoniation (to reduce odor and prolong shelf life)

- Quality control sampling

This ensures a clean, consistent base material the foundation of a durable mattress core.

3. Molding Into Mattress Cores

Here’s where innovation meets tradition. The latex is poured into precision-engineered molds based on client specifications. We offer:

- Single-zone and multi-zone core designs

- Custom density requests (from soft to extra firm)

- Variable core sizes (twin to king, European specs, and more)

4. Curing, Washing & Drying

After molding, every core is:

- Cured to stabilize internal structure

- Washed multiple times to remove residual proteins or impurities

These phase process enhances:

- Durability

- Cleanliness (ideal for allergy-sensitive markets)

- Resistance to sagging

5. In-House Quality Testing

At MAUS, we don’t outsource quality we own it. Each batch undergoes:

- Density and compression testing

- Tear and rebound tests

- Visual and structural inspections

💡 Every latex core is certified and batch-traceable, with documentation provided upon shipment.

6. Packaging & Export Preparation

Our cores are packaged according to your shipping preferences:

- Flat-packed or rolled

- Vacuum-sealed if requested

- Labeled for easy warehouse identification

7. Global Delivery, Local Support

We’ve delivered latex mattress cores to partners across:

- The United States

- Australia

- MIddle East

- Singapore & Malaysia

Why This Journey Matters for Your Brand

Choosing a supplier is about more than specs it’s about transparency, reliability, and scale. By understanding our full production journey, you can trust every MAUS product that lands on your factory floor.

Let your next mattress core start where quality begins in the heart of Malaysia.